Automotive & Marine Busbar Selection: Optimizing Low-Voltage DC Power Distribution

- November 22, 2025

- 532

The Critical Node in DC Architecture

In the engineering of electrical systems for special purpose vehicles, marine vessels, and off-grid power banks, the Power Distribution Block (or Busbar) is often the most underestimated component. However, it serves as the critical node that determines the safety, organization, and expandability of the entire DC circuit.

This guide provides a technical framework for selecting Insulated Power Distribution Blocks for 12V, 24V, and 48V DC systems. It is intended for system integrators, fleet upfitters, and marine engineers looking to optimize cable management and ensure compliance with safety standards.

(Note: This guide focuses exclusively on mobile/low-voltage DC applications and does not cover industrial AC switchgear components.)

1. The Hierarchy of Amperage: Matching Capacity to Load

The primary specification for any busbar is its Continuous Current Rating. Undersizing this component is a common failure mode that leads to excessive heat generation and voltage drop. When specifying a busbar, the total potential load must be calculated with a safety margin (typically 20%) for ambient temperature variables.

We categorize distribution blocks into three performance tiers:

Tier 1: Sub-System Distribution (150A – 250A)

-

Target Application: Sub-panels, dashboard electronics, LED lighting arrays, and auxiliary accessory power.

-

Design Priority: Compact footprint. These blocks are designed to fit in tight spaces (e.g., behind consoles or in glove boxes) while maintaining full conductivity.

Tier 2: Heavy-Duty Distribution (300A – 400A)

-

Target Application: The backbone of most RV and Marine house battery banks. Suitable for connecting alternators, DC-DC chargers, and mid-sized inverters (up to 2000W).

-

Design Priority: Thermal mass and structural rigidity. The base must be reinforced to withstand the torque required to secure 2/0 AWG or 4/0 AWG cables without cracking.

Tier 3: High-Demand Industrial (500A – 600A)

-

Target Application: Commercial vessels, large lithium battery arrays, and heavy industrial machinery (e.g., hydraulic pumps, winches).

-

Design Priority: Maximum cross-sectional copper area. These units are engineered to handle continuous high-amperage flow with minimal resistance, ensuring system stability under peak loads.

2. Optimizing Harness Design: The “Hybrid” Configuration Advantage

A significant challenge in modern harness design is the disparity in cable gauges. A centralized node often needs to connect massive battery cables alongside thin sensing wires. Using a standard 4-stud busbar forces installers to “stack” dissimilar terminals, which compromises contact integrity.

The Solution: High-Density Hybrid Configurations

To resolve this, advanced distribution blocks now feature a hybrid layout that integrates two types of connection points on a single chassis:

-

Primary Studs (M8 / M10):

-

Purpose: High-current input/output.

-

Compatibility: 0 AWG to 4 AWG cables (e.g., Battery, Inverter, Bow Thruster).

-

-

Auxiliary Screw Terminals (#8-32):

-

Purpose: Low-current distribution.

-

Compatibility: 8 AWG to 16 AWG wires (e.g., Voltage sensing, Bilge pumps, LED controllers).

-

Engineering Benefit: This configuration reduces the component count in the BOM (Bill of Materials), saves valuable mounting space, and eliminates the safety risk of stacking ring terminals.

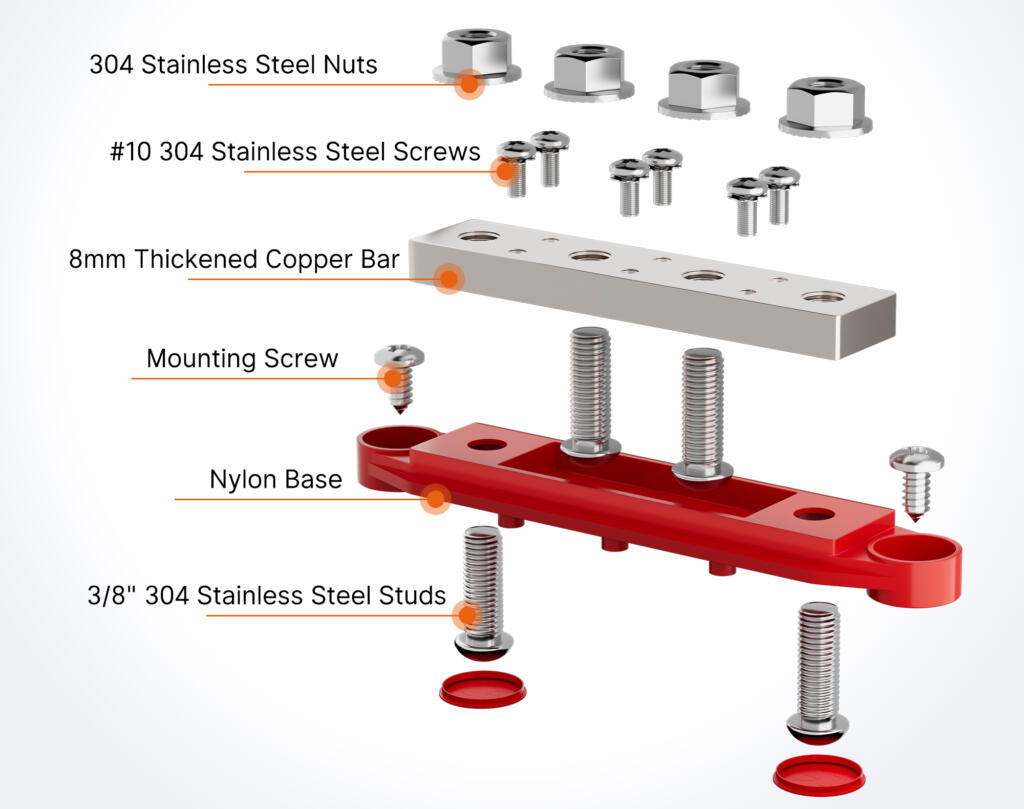

3. Material Science: Conductivity and Environmental Resilience

In mobile applications, components are exposed to vibration, thermal cycling, and often corrosive environments (salt spray). Material selection is non-negotiable.

-

Conductive Plate:

-

Brass vs. Copper: While brass is cost-effective, copper offers superior electrical conductivity (lower resistance). For high-amperage applications (>300A), copper is the preferred substrate to minimize heat rise.

-

Surface Treatment: Bare copper oxidizes rapidly. Professional-grade busbars feature Tin-Plating or Nickel-Plating. This provides a sacrificial barrier against oxidation, ensuring low contact resistance over the vehicle’s service life.

-

-

Insulation Base:

-

The housing material must offer high dielectric strength and thermal stability. Glass-Fiber Reinforced Nylon (PA66) is the industry standard, offering a UL94 V-0 flammability rating to prevent melting under fault conditions.

-

4. Installation Best Practices for System Safety

Selecting the right product is only half the equation. Proper installation is vital for compliance with standards such as ABYC E-11 (Marine) or SAE J1939 (Automotive).

-

Overcurrent Protection: A busbar is a distribution point, not a protection device. A main fuse (ANL, Class-T, or MRBF) must always be installed on the positive feed cable before it enters the busbar.

-

Torque Specifications: Loose connections create high resistance spots that lead to arcing and fire. Installers should adhere to the manufacturer’s torque specifications (e.g., 15-20 Nm for M10 studs) and use split washers or lock nuts to prevent loosening due to vibration.

-

Protective Covers: To prevent accidental short circuits—for example, a dropped wrench bridging the positive busbar to the chassis ground—insulating covers are mandatory for positive distribution blocks in most regulated sectors.

Conclusion

The Power Distribution Block is a foundational element of any robust DC electrical system. By moving away from generic, low-spec components and selecting application-specific, high-density busbars, OEMs and installers can significantly improve system safety, reduce assembly time, and enhance the overall reliability of the vehicle or vessel.

Daier offers a comprehensive range of heavy-duty distribution blocks, from compact 150A units to industrial 600A systems, featuring various stud and screw combinations to match any wiring harness design.

View Our Technical Catalog: Heavy-Duty Power Distribution Blocks